More Basics

Before we dive right on in, there are a few more basic components that we should go over.

Switch Positions

Normally Open (“NO”)

A “Normally Open” switch is as it sounds. In its normal state, the contacts inside the switch are open. When actuated, the contacts close.

Normally Closed (“NC”)

A “Normally Closed” switch is, again, as it sounds. In its normal state, the contacts inside the switch are closed. When actuated, the contacts open.

Both types of switches are used throughout appliances, and have various applications. For instance, the light switches in a fridge. When you open the door, the lights go on. When you close the door, the lights go off.

In it’s normal state, a fridge light switch is generally a NC switch. The plunger is not engaged, so a spring is pushing it out. When that plunger is pushed out, the contacts are closed, and line voltage is then supplied to the lights. When the customer shuts the door, the door pushes the spring loaded plunger in, and it opens the electrical contact and the lights go out.

Relays

Relays, in their most basic sense, are electrically controlled switches that control a high-power circuit using a low-power signal. They allow a small voltage to activate a much larger load. What do I mean by this? Let’s dive into relays a bit deeper, and it should make sense.

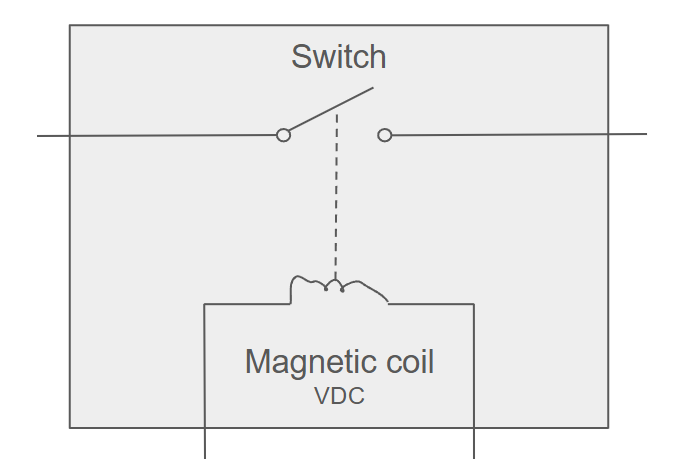

Relays come in NO and NC configurations. The switch itself that opens and closes the high voltage circuit is spring loaded, but it has a magnet on the switch itself. The magnetic coil, when energized, pulls the switch downward and closes the circuit (in an NO configuration).

In the diagram above, you can see the switch at the top. Line or neutral to the load in particular is connected through that switch. This is no different than the switch on the wall in your house. It’s sole purpose is to open and close a circuit, and to provide the least amount of resistance when the contacts are closed.

That said, when we have a control board in an appliance, we want to minimize the current flowing through the board itself. Control boards usually operate on low voltage, and the relay isolates the low voltage side from the higher voltages. So, relays are used.

Relays allow for separation of the high voltage loads. All the control board needs to do in order for the relay to close the circuit is to supply a small DC voltage to the magnetic coil in the relay.

When it does that, the magnet energizes, and the corresponding magnet on the switch is then pulled down to that magnet, and the switch it closed. The magnetic coil and the switch are completely isolated from one another.

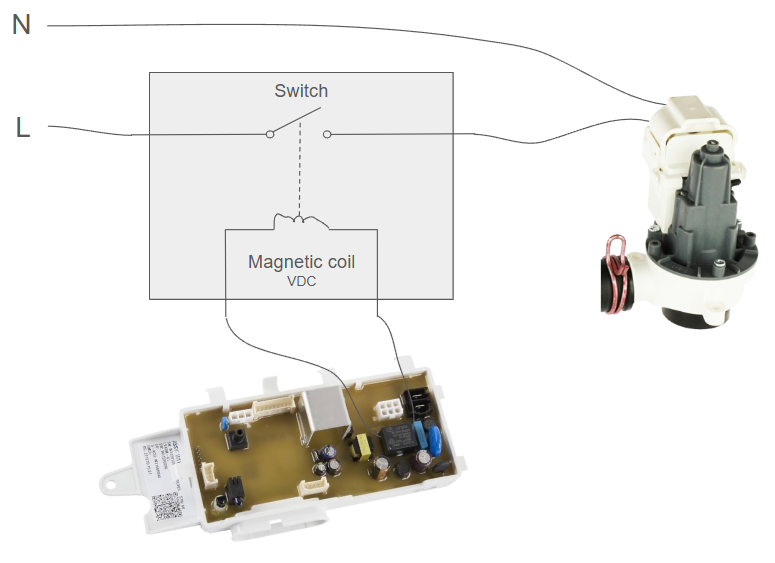

Now, let’s look at an overly simplified visual of how the relay is working in the grand scheme of things.

As you can see, line voltage is routed through the switch on the relay. And the control provides the DC voltage to the magnetic coil, which then opens and closes the switch.

Technically speaking, line voltage comes into the board through the black connector, then the traces (“traces” are the conductive pathways on the board) connect the line voltage to the relay. But it is done in such a manner as to isolate that high voltage from the low voltage.

Triacs

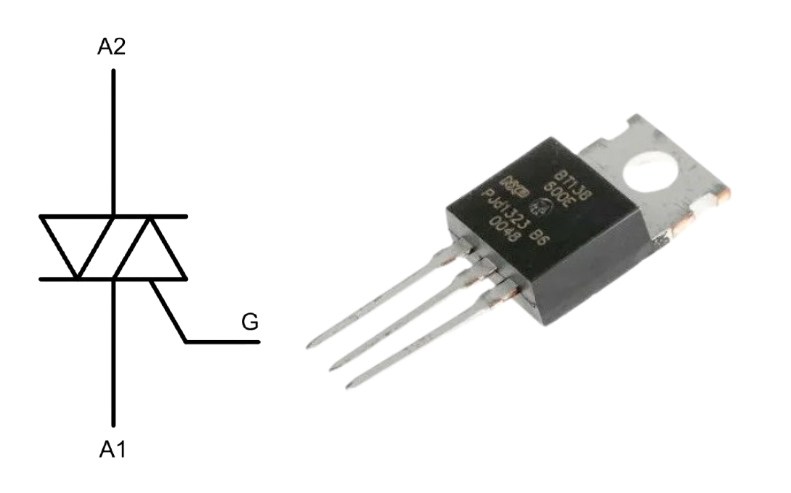

A triac (Triode for Alternating Current) is a solid-state electronic switch used to control AC power. Unlike a relay, a triac has no moving parts and can switch on and off rapidly, making it ideal for controlling loads like heating elements, valves, and small motors. You will see these on wire diagrams and used in appliances, and it’s important to understand how they work. They operate differently than relays.

-

A triac acts like an electronic gate, allowing AC current to pass through when triggered by a low-voltage control signal.

-

Unlike a mechanical relay, a triac requires a load to be present to operate correctly. This is because a triac relies on the flow of current through the circuit to remain conductive; if there is no load (or if the load is too small), the triac may not fully turn on or off properly. You might very well see incorrect voltages due to a failing load or a wiring issue.

-

Triacs only work with AC power because they can switch on both halves of the AC cycle, making them ideal for variable control applications like dimmers and speed controls.

- Triacs are much faster, and much more precise than relays are.

Relays vs. Triacs

-

Washing Machines → Relays for Drain Pumps

-

The drain pump in a washing machine often requires a relay because it handles higher current loads and may operate on DC power in some models. The relay provides strong isolation and reliability for such applications.

-

-

Dishwashers → Triacs for Water Valves

-

Many dishwashers use triacs to control water inlet valves and detergent dispensers because these components require fast, precise switching, and they work well with AC power. Triacs are also more reliable in environments where frequent switching is needed.

-

In short, relays are best for high-power, high-isolation applications, while triacs are ideal for fast, quiet, and efficient AC switching in lower-power applications.

For a much more detailed overview of what triacs are and how they operate, view the Quick Reference Guide article on Triacs.