Professional Appliance Repair Training

Learn Refrigerator Repair

Master The Cooling Loop

Demystify the physics of cooling. If you want to learn refrigerator repair correctly, you must understand the entire thermodynamic cycle. From modern Inverter Compressors to classic Defrost Circuits, learn to determine if it’s an electrical failure or a sealed system issue.

Start This Course

Is It The Compressor or The Board?

Refrigeration is about heat removal. To learn refrigerator repair effectively, you have to distinguish between airflow restrictions, defrost failures, and major system failures. We teach you the “Process of Elimination” so you don’t misdiagnose the problem.

Defrost Systems

The #1 cause of “Warm Fridge / Cold Freezer.” Learn to troubleshoot the heating element, the bimetal termination thermostat, and the Adaptive Defrost Control (ADC). Learn how to force a manual defrost to prove your diagnosis instantly.

Inverter Inputs

Inverters aren’t magic. They just need the right signal to run. We teach you how to test the input voltage (DC) and frequency signal cables (Hz) to ensure the inverter is getting exactly what it needs to work.

System Isolation

Stop guessing. We teach you the diagnostic steps to definitively determine if you are looking at a sealed system leak/restriction, or if it is purely an electrical component failure. Never condemn a good compressor again.

Diagnostic Strategy

Sealed System Identification

This course focuses on electrical and component diagnostics. However, understanding how to identify a sealed system failure is critical so you don’t waste time troubleshooting control boards on a unit with a gas leak.

We teach you to read “Frost Patterns.” A full frost pattern means the system is healthy. A partial frost pattern is the smoking gun of a refrigerant leak. We teach you to spot the difference in seconds by inspecting the evaporator coil.

- ✓ Interpreting Partial Frost Patterns

- ✓ Compressor Amperage Signatures

- ✓ Condenser Heat Transfer Checks

Electrical Analysis

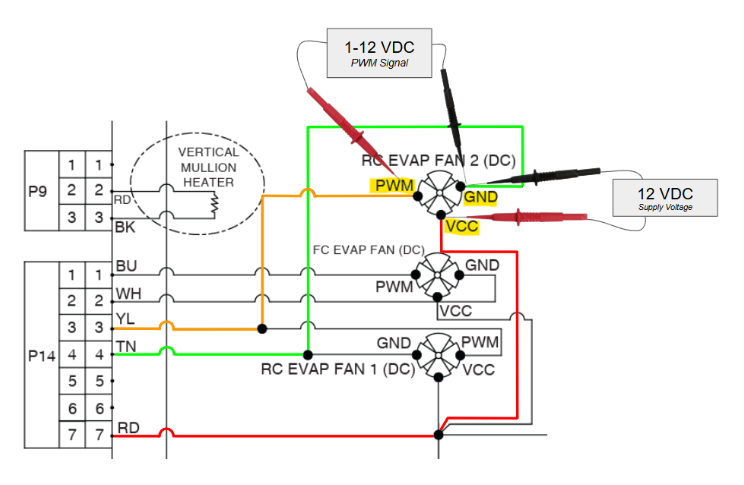

Fans, Relays & Sensors

Modern refrigerators are full of DC fans and NTC sensors. Learn to diagnose if the board is sending the correct voltage, or if the component itself has failed.

When you learn refrigerator repair with ATA, you learn to trust your meter. We teach you how to condemn a bad main control board through a strict process of elimination, verifying inputs and outputs before you order expensive parts.

View The Syllabus

See The Training In Action

Supplement your coursework with deep technical dives. Check out our free resources for diagnostic examples and theory.

Diagnostic Videos

Watch step-by-step troubleshooting guides, live multimeter testing, and component teardowns.

100% Positive Rating

Viewer approved help

Tech Podcast

Deep dives into the science of repair. We break down electrical circuits, schematics, and error codes.

“Amazing info! Thank you for the hard work”

— Jp Rivera, Listener

Start Your Journey

Choose Your Training Path

The Refrigerator Repair module is included in our Certified Professional bundle.

Fundamentals

Perfect for beginners. Learn electrical theory, multimeter usage, and the core “Theory of Operation.”

- ✓ Electrical Theory Basics

- ✓ Multimeter Training

- ✓ Self-Paced Access

Certified Professional

Master diagnostics, schematics, and business skills. Includes the Refrigerator Module and certification.

- ✓ All Repair Modules (Fridge Included)

- ✓ Microwave Course Included (Free)

- ✓ 1-on-1 Mentorship Sessions

- ✓ ATA Official Certification

Microwave Specialist

Add high-voltage microwave diagnostics to your skillset. Safe discharge procedures and magnetron testing.

- ✓ High Voltage Safety

- ✓ Magnetron Diagnostics

- ✓ Door Interlock Switches